Dies for Foil Stamping, Embossing, & Custom Dielines

Custom touches like foil stamping, embossing, or dielines can promote your business or message in an attention-getting way. Luxury brands utilize these techniques to impress their customers. Others add these techniques to impart beauty and elegance to their stationery and marketing projects. All of these techniques require that your graphic designer make black-&-white artwork from which metal dies will be made. The metal dies will then be applied to paper in unique ways to create each type of effect. This article will discuss each kind of die separately.

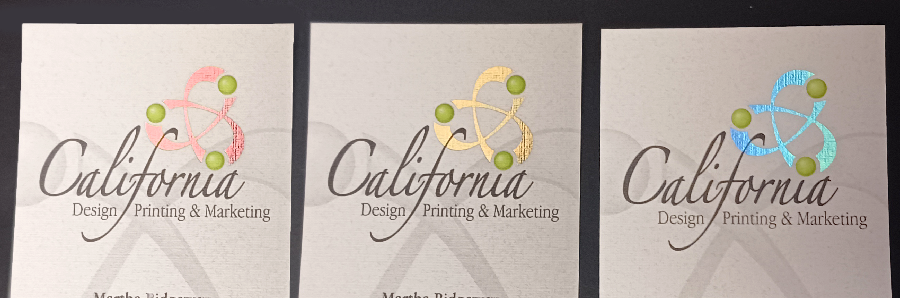

Foil Stamping Dies

The foil stamping effect requires a roll of foil with multiple layers. There is a base liner, also called the release layer. In the middle is a glue layer and lastly, the pretty foil layer. The procedure involves spreading out a roll of foil onto a piece of paper, then applying heat and pressure to cause the foil to adhere to the paper. The die is then applied to cut away any foil that is not part of the desired shapes or words.

Foil comes in many colors. The most popular foils are the simulated metals: gold, silver, bronze, and copper, with many variations of them all. You can get foil in lots of solid colors, too. Royal blue is seen quite often. Solid colored foils can have either a matte or shiny finish. Holographic foils that change color as you move the paper are also available. Some denominations of American paper money have holographic or metallic foil stamping. Check your wallet for examples!

Embossing & Debossing Dies

The embossing effect is created when pressing flat sheets of paper between two components of a die to raise an image above the surface of the paper. When the image is lowered below the surface of the paper, it is called, “debossing”. In either case, corresponding metal dies are made that fit together exactly, like a hand in a glove. One die pushes the shape or word up into the paper (the hand) and the other does the same thing, but in a downward direction (the glove). When no printed ink or foil accompanies the embossing, it is called “blind emboss/deboss”. “Registered embossing” is when the dies must line up exactly with printed shapes and words or with foil stamping. Foil stamping is often combined with embossing.

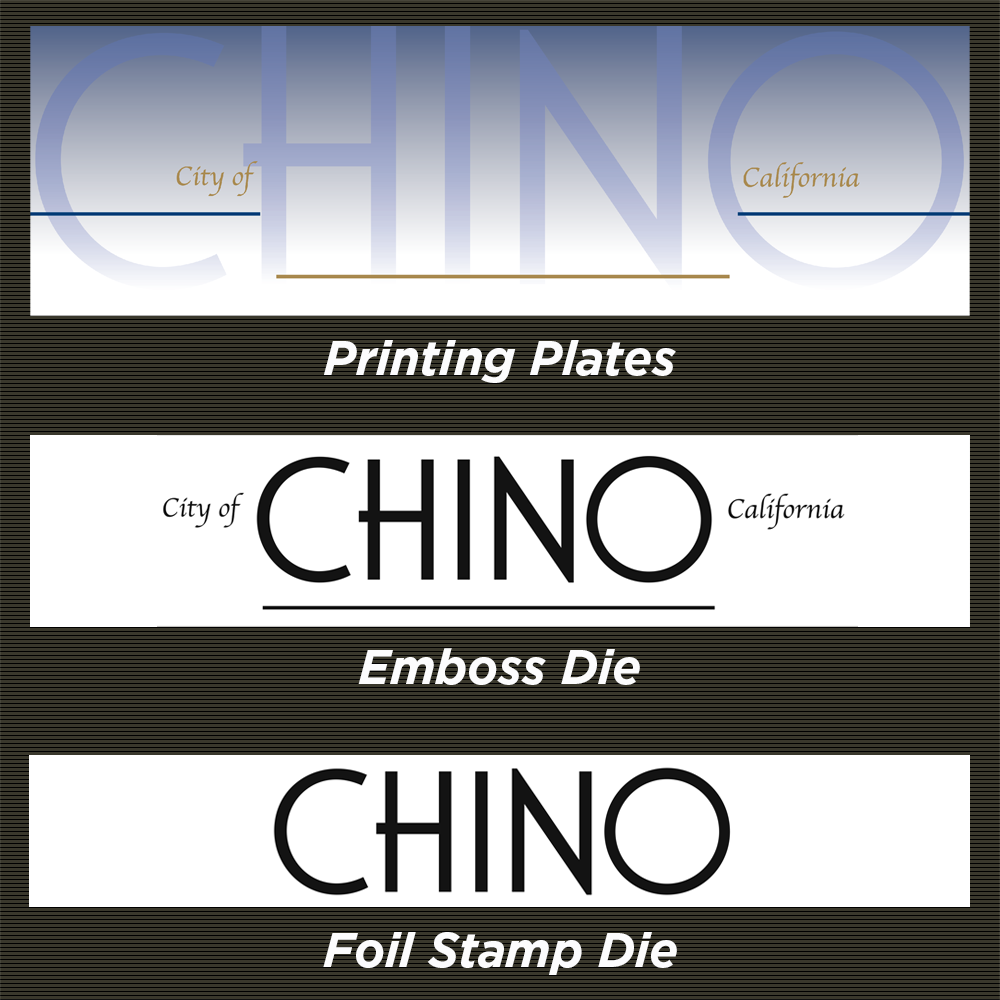

A Combination of Effects

Above is a certificate we produced that combines printing, foil stamping and registered embossing. In this example, the embossing is most easily seen on the raised edges of the foil stamped letters.

The graphic designer must make a separate artwork for each process, and all the pieces must line up exactly. Shown below are the art files for the printing plates, the foil stamping die, and the embossing die. The Printing Industry Exchange has a nifty article that discusses foil stamping and embossing dies at length. Their article adds crucial information regarding the technical requirements for setting up the art files for the dies and selecting the paper.

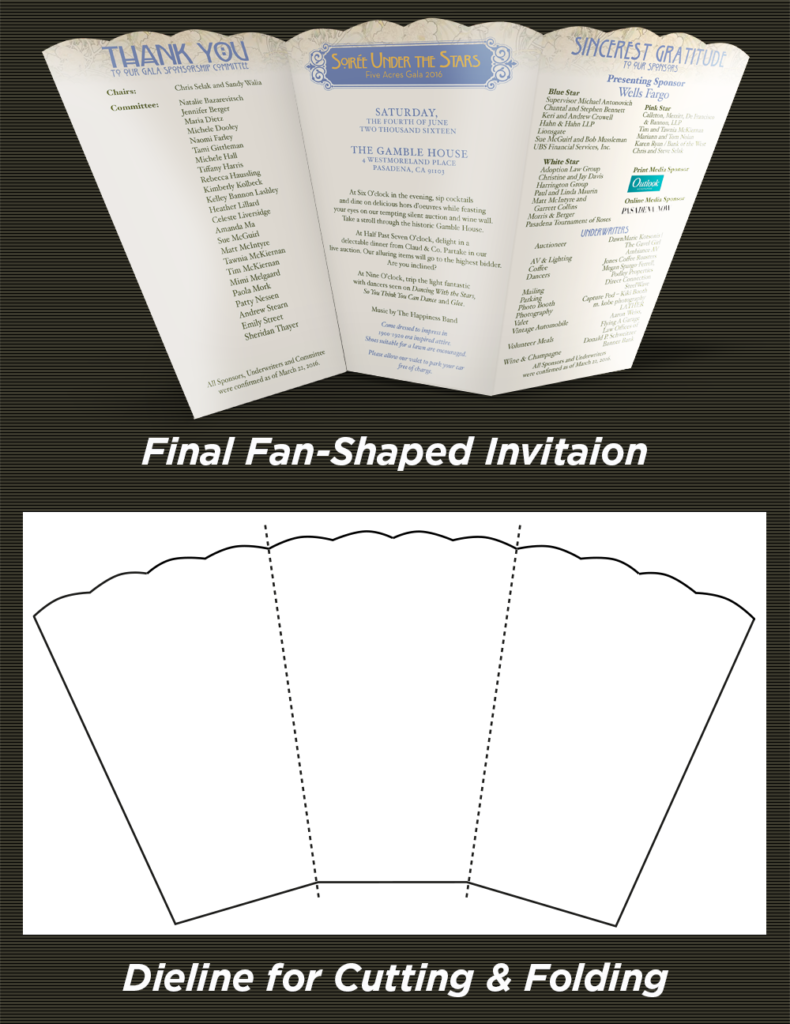

Custom Dielines

Standardized dielines are available to make presentation folders, window envelopes, doorhangers, and corrugated boxes. But our customers often request custom dielines for unique folds and cutouts. Below is an example of an invitation in the shape of a scalloped-edged fan. The first step in creating this custom dieline was to make black-&-white artwork. The solid lines represent the dieline for the cutout. The dotted lines represent the dieline for the angled folds.

In Conclusion

Such custom touches as these are only offered by commercial printing companies. Our graphic designers are creative, technically proficient and able to create all the printing plates and dies that you will need for your next elegant project!